CSUN’S Experimental Mechanics Lab Creates the Future

Mechanics is something we may not all understand, but it is universal to our everyday experiences. For example, the pushing of rubber on an asphalt road by using oil and metal as force for a car is mechanics at work.

But what about using glass and plastic to make a prosthetic limb? Or pressing rings of different mixed materials to generate magnetism? This new frontier in mechanical engineering is coming to the forefront in California State University, Northridge’s Experimental Mechanics Lab (EML), run by mechanical engineering professor George Youssef.

“Really, we are focusing on the deformation and behavior of nontraditional materials,” Youssef said.

In laymen’s terms, Youssef’s lab analyzes how different materials – such as glass and wood – interact and create something innovative and novel for the engineering world.

“Our biggest focus is trying to understand how we can use mechanical deformation to create coupling between electricity and magnetism, called strain mediated electromagnetic coupling (SMEC),” he said.

Youssef and student members of the lab have been working to create an energy source without using an electric current, replacing it with electromagnetism. This method is more energy efficient, and could be used to replace anything from cellphone batteries to car motors, he explained.

“All the devices that we use on a daily basis are based on electrical current,” Youssef said. “When you work on your phone, it gets hot. That is a sign that there is a lot of loss of energy.”

The SMEC project, instead, uses two ring-shaped materials working together to create an electromagnetic field to power objects.

The inner material uses an electric field, or voltage, while the outer uses strain to create magnetism. The outer ring gets squeezed and forces its magnetic current into the voltage of the inner ring, creating a mechanically driven voltage, which will not stop until the pressure is lessened.

“You would have a power source not based on current, like cell phones are right now, but on voltage,” Youssef said.

One of the added benefits of the project, if successful, is a cell phone wouldn’t get hot anymore, since no energy is wasted with this new power method.

Youssef explained the materials being studied by the lab are of interest to the United States Navy. While they don’t have funding yet, he hopes the research will inspire funding in the future.

“In a lab like ours, you try to get your name outside so they can trust your work,” he said.

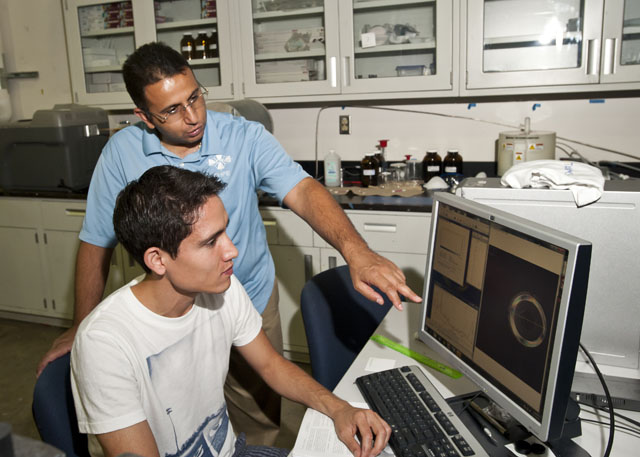

The biggest asset to the lab is not the research, he said, but the students.

“We are heavily interested in them,” Youssef said. “Research is different than teaching. We take more of a mentor and adviser role. In [each student’s] project, they are the main drivers. We try to guide them, not do the work for them. The point is to make great engineers for the field.”

Since the lab opening in January 2012, 30 undergraduate students have conducted research, and seven graduate students have completed their thesis projects and moved on to careers in the engineering field, Youssef said.

Cesar Lopez is a mechanical engineering master’s student with more than three years of research training with Youssef.

Lopez is collaborating with Cedars-Sinai researchers in the biomechanical field for his project. Specifics of the project are kept under wraps since Lopez is hoping to apply for a patent once it is complete.

“I wanted to work with something on the human body. It’s something that appealed to me, but I didn’t know anything about composite materials,” Lopez said. “Now, I consider myself an expert, thanks to Dr. Youssef. I feel confident about what I’m doing. You get exposed to different projects and machinery.”

Youssef described Lopez’s master’s project as “completely innovative” and something that could be used to help advance human biomechanics.

“He is almost done with his project,” Youssef said. “He made these [composite material] samples and he created the experimental setup. He is proving the concept that this new material can be used for a specific useful application.”

Lopez attributed his successes to Youssef’s advisement over the last few years.

“He taught me to think like an engineer. You have to see a problem from different points of view,” he said. “My next step is to continue working in biomechanics, but also stay connected to Dr. Youssef and the lab. This is something that we started together. I feel like a part of the lab. I want to still be part of it.”

experience

experience